- R&D Laboratory Equipment (연구 & 실험용 제품)

- 균질기/분산기

Homogenizers/Dispersers - 필믹스(나노입자)

Thin Film Spin System High Speed Mixer - 호모믹서/디스퍼/로보믹서

Homo Mixer/Disper, ROBOMIX - 울트라믹서/호모믹서/호모디스퍼

Ultra Mixer/Homo Mixer/Disper - 아지호모믹서

Vacuum/Temperature control AGI Homo Mixer - 초음파분산기/파쇄기

Sonicators/Ultrasonic Processors - 고압균질기

High Pressure Homogenizers - 공전.자전 원심 교반 탈포기

Planetary Centrifugal Mixers - 고점성믹서/공전.자전형믹서

Hivis & Planetary Mixers - 교반기/아지믹서

Overhead Stirrers/AGI Mixers - 분쇄.그라인딩밀

Mill/Grinder/Blender - 초음파세척기

Ultrasonic Baths - 회전(증발)농축기

Rotary Evaporators - 진공펌프/조절기

Vacuum Pumps/Controller - 항.냉 순환/온도조절장치

Circulator, Chiller

- 균질기/분산기

- QC&QA Analysis Equipment (분석용 제품)

- Laboratory & Pilot Reactors(실험용&생산용반응기)

- Pilot & Process Equipment (생산및프로세스장비)

> 제품소개 > R&D Laboratory Equipment (연구 & 실험용 제품) > 고압균질기-High Pressure Homogenizers

> 제품소개 > R&D Laboratory Equipment (연구 & 실험용 제품) > 고압균질기-High Pressure Homogenizers고압균질기-High Pressure Homogenizers

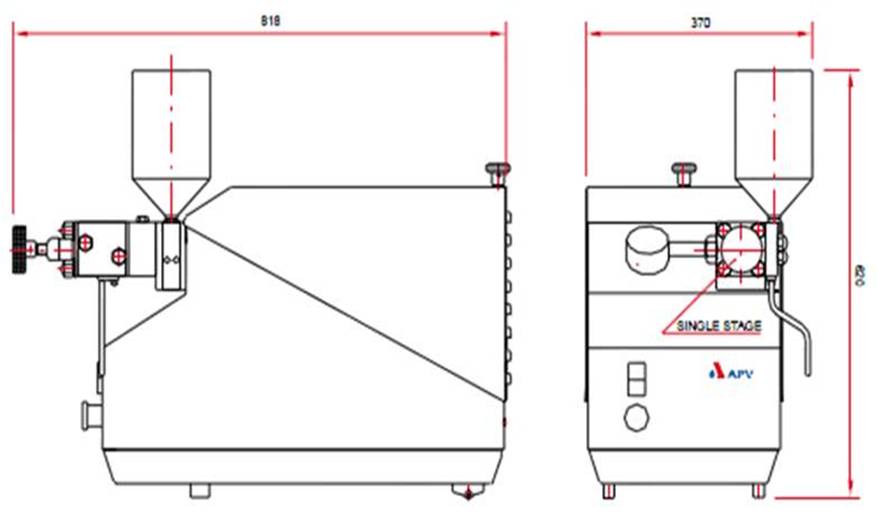

APV1000/2000 고압균질기(High Pressure Homogenizer)

|

- 제조사

- : APV, Germany

| Cat.No. | Description | |

|---|---|---|

| 1000-SS | APV 1000 - Single Stage Valve | [견적요청] |

| 1000-TS | APV 1000 - Two Stage Valve | [견적요청] |

| 2000-SS | APV 2000 - Single Stage Valve | [견적요청] |

| 2000-TS | APV 2000 - Two Stage Valve | [견적요청] |

- 120년 역사의 덴마크 APV 제품으로 내구성이 뛰어남

- 식품, 유가공, 화장품, 제약 등의 고품질 나노유화에 최적

- 유화, 나노리포좀 및 세포파쇄용으로 사용

- 최대 1000bar /2000bar 에서 사용 가능

- 용도에 따라 1 stage와 2 stage 선택 가능

- 생산용으로 scale up

- 샘플 테스트 가능

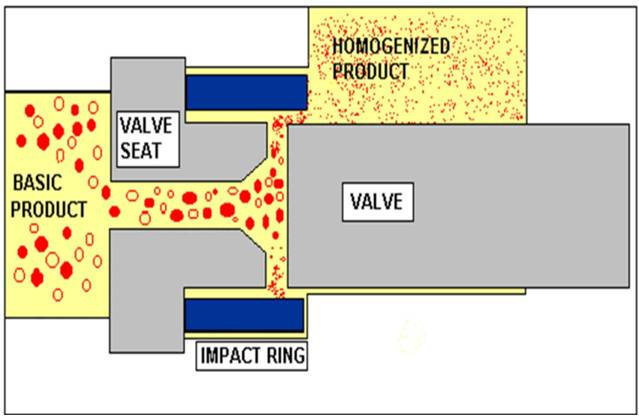

고압균질기(High Pressure Homogenizer)는 균질하고자 하는 초기 물질(E)이 고압, 저속으로 밸브 시트, Valve Seat (B)로 유입이 되며, 아주 미세한 간극을 유지하도록 호모밸브, Homo Valve(A)로 압력을 조절하여 호모밸브시트, Homo Valve Seat(B)로 흘러들어감에 따라서, 저압.고속으로 변함입니다. 이러한 압력과 속도의 차이로 인한 Cavitation 효과로 유화.분산이 일어나며, 임팩트링(C)을 통하여 처리된 유화.분산물(F)이 나오게 됩니다.

압력과 속도의 변화는 주사기에 물을 넣고 토출구를 손으로 막고 피스톤은 눌렀을 때와 토출구를 막지 않고 피스톤은 눌렀을 때의 상황을 생각하시면 쉽게 이해가 되실 것입니다.

.jpg)

균질화(Homogenization)는 제약, 바이오, 화장품, 식품, 유가공, 화학 등 전분야에서 다양물 samples을 처리하는데 사용됩니다.

이러한 처리물들은 대체로, 유화(Emulsifying), 균질(Homogenizing), 분산(Dispersing), 세포 파쇄(Cell disruption)로 구분됩니다.

유화는 서로 섞이지 않는 다른 액상 (예, 물과 기름)을 균질화 하는 작업을 의미하며, 분산은 액상에 녹지 않는 고상 (예, 물속에 수산화마그네슘 (Mg(OH)2)을 균질화 하는 작업을 말합니다.

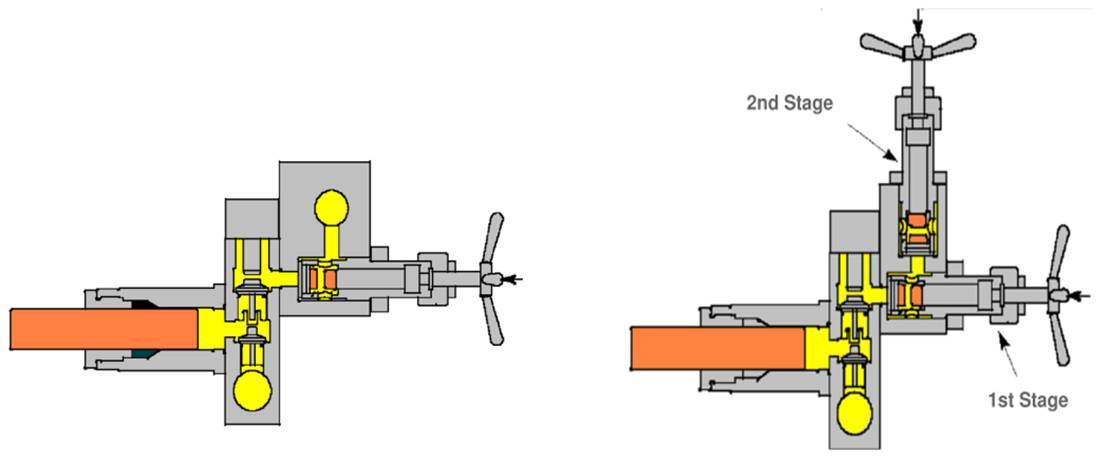

APV 실험용 고압 균질기는 2 종류의 제품이 있으며, 최대 처리 압력에 따라 1000 bar 모델과 2000 bar 모델로 구분이 됩니다.

각 모델에 사용하는 목적에 따라, Single stage valve 제품과 Two stage valve 제품으로 세분화 됩니다.

각 압력에서 처리하고자 하는 물질의 특성에 따라서 Single stage 또는 Two stage 제품을 선택할 수 있습니다.

즉, 호모게나이징 밸브(Valve)가 1개 있는지 2개 있는지의 차이로 이해를 하시면 됩니다.

※ Single stage 제품의 경우에는 주로, "분산(dispersion)"이나 "세포 파쇄(Cell disruption)"를 목적으로 사용하는데 주로 사용되며, 주로 550 bar (8,000 psi) 이상의 고압에서 처리할 때 사용됩니다.

.jpg)

.jpg)

※ Two stage 제품의 경우에는 주로 "순수 유화(emulsion)"를 목적으로 사용이 되어지며 550 bar (8,000 psi) 이하에서 처리할 때 사용됩니다.

유화를 목적으로 하는 경우에는, second stage valve가 재응집되는 것을 막아주고 입자사이즈를 더 균일하게 만들어 주는 데 도움이 되며 2차측 부분의 압력을 원하는 설정 압력의 약 10 ~ 20% 수준으로 맞추어 주는 것이 효과적입니다.

하기의 그림을 참고하십시요.

.jpg)

.jpg)

[2 stage valve를 사용한 다음 재 응집이 되지 않음] [2차측 valve의 압력은 10 ~ 20%로 사용했을 때, 효과가 제일 우수함]

.jpg)

.jpg)

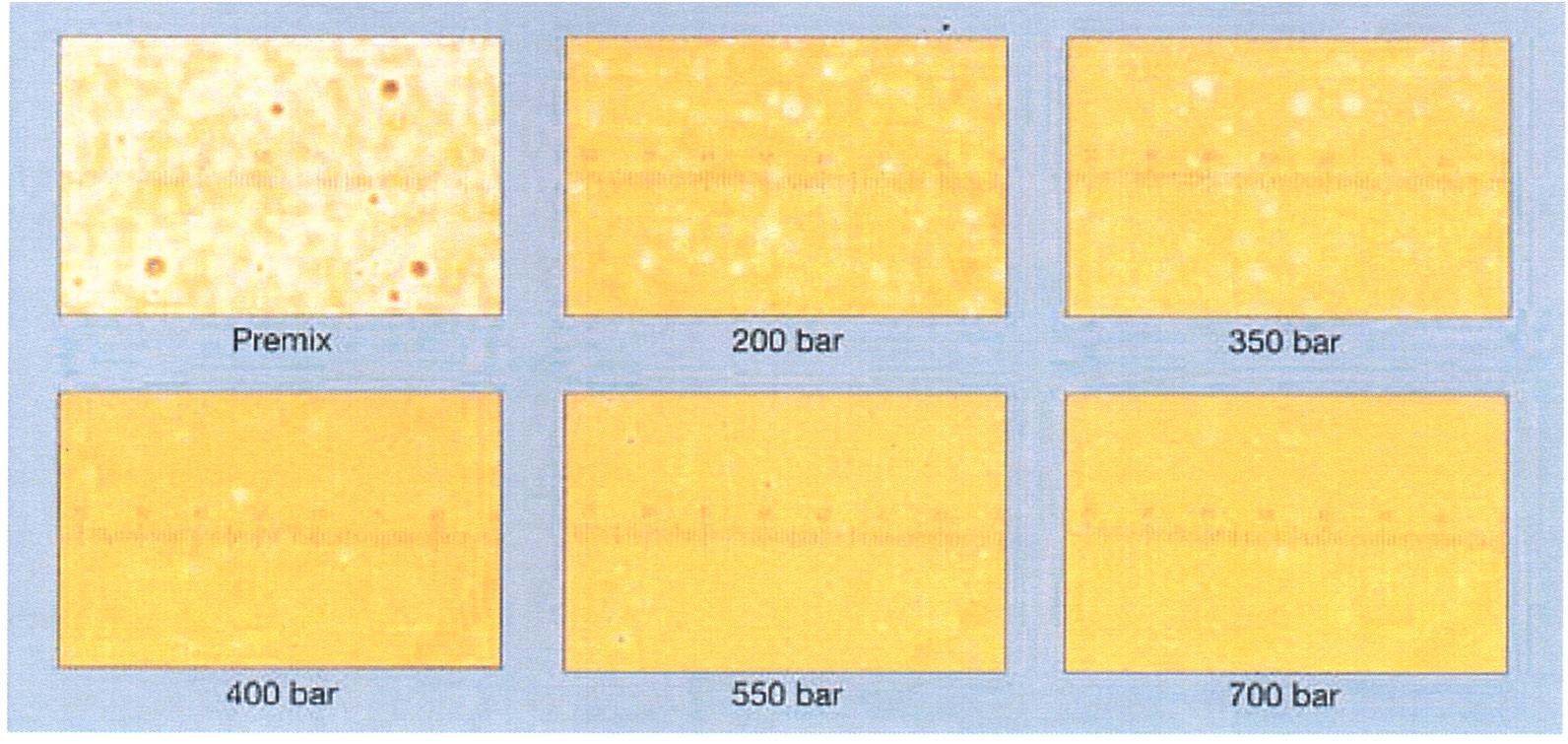

Oil in Water (O/W) Emusion : 고압균질기 사용 前 과 사용 後의 사진입니다.

Homogenizing valve (호모게나이징 밸브), Impact ring (임팩트 링) 및 Homogenizing valve seat (호모게나이징 밸브 시트)는 처리하는 물질의 특성에 따라서 하기의 재질로 선택이 가능합니다.

- Ceramic (세라믹) : high pressure application up to 700 bar (standard)

- Tungsten carbide (텅스텐 카바이드) :

- Stellite (스테릴라이트) : disruption of single-cell micro organisms, subsequent release of proteins and enzymes

※ 고압균질기를 이용하여 점성(Viscosity), 입도 사이즈 (Particle Size) 및 분산 안정성 (Stability)은 하기의 업무 수행에 따라 다양해 질 수 있습니다.

1)전 처리 업무 (Pre-Mixing Process)

: 고압균질기로 유입되는 전처리되는 물질의 입자 사이즈는 10 um 이하여야 효과가 좋습니다.

: Application에 따라서, 독일 YSTRAL社 균질.분산기(Homogenizer/Disperser) 및 일본 PRIMIX社 호모믹서(Homo Mixer) 사용 제안.

.jpg)

.jpg)

2)처리 온도 (Process Temperature)

: 유화(emulsifying)의 경우, 처리물의 온도를 60 ℃에서 하시면 더 좋은 결과를 얻을 수 있습니다.

3)계면활성제(Surfactant : Emulsifying agent or stabilizer)의 사용 유.무, 함량 및 종류

4)사용 압력 (Operating Pressure)

.jpg)

5)처리 회수 (Number of Passes)

.jpg)

APV 고압균질기의 주요 사용고객입니다.

[납품된 제품 사진]

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

Dairy Products_Extended shelf stability, improved smoothness and body

■ Milk ■ Desserts ■ Ice cream ■ Sour cream ■ Cream ■ Cheeses ■ Yoghurt ■ Condensed milk

Foods and Beverages_Improved viscosity control and shelf stability, reduced ingredient cost

■ Fat substitutes ■ Baby foods ■ Dressings ■ Vegetable juices ■ Tomato products ■ Peanut butter ■ Reduced fat products ■ Flavours and fragrances

■ Fruit juices ■ Sauces ■ Egg products ■ Beverage emulsions ■Nutritional supplemnets

Healthcare and Cosmetics_Smoother textures, better dispersion of thickeners, enhanced colour, increased gloss, better application.

■ Hair products ■ Lotions ■ Conditioners ■ Nail polishers ■ Skin creams ■ Shampoos ■ Lipsticks ■ Liposome emulsions

Pharmaceuticals_Stability, uniformity, narrow particle size distruction, enhanced texture.

■ Antibiotics ■ Creams ■ Ointmetns ■ Liposomes ■ Veterinarial preparations ■ Antacids ■ Intravenous emulsions ■ Tablet coatings ■Nutritional supplements

Chemicals_Particle size and viscosity control, enhanced colour, uniformity of application and improved stability.

■ Disinfectants ■ Insecticides ■ Silicone emulsions ■ Lubricants ■ Latex ■ Pigment dispersions ■ Emulsifiers ■ Specialty paints and coatings

■ Wax emulsions ■ Resins/rosins ■ Viscosity index improvements ■ Inks

Biotechnology_Cell disruption for harvesting high yields of intracellular products.

■ Bacteria (E-Coli) ■ Proteins ■ Yeast (Cerevisiae) ■ Algae ■ Enzymes

| APV-1000 | APV-2000 | |

| Max. pressure | 1000 bar 14,500 psi 100 MPa |

2000 bar 29,500 psi 200 MPa |

| Capacity | 22 liters/h | 11 liters/h |

| Min. sample volume | 150 ml | 100 ml |

| Hold-up volume | 13 ml | 13 ml |

| Noise level | 70 dB | 70 dB |

| Fluid end | Duplex stainless steel | Duplex stainless steel |

| Plunger | Ceramic 14 mm 70 rpm |

Ceramic 10 mm 70 rpm |

| Pump valve seats | Tungsten carbide | Tungsten carbide |

| Homo valve Homo valve seat Impact ring |

Ceramic | Ceramic |

| O-rings | EPDM | EPDM |

| Back-up rings | POM (acetal polymer) | POM (acetal polymer) |

| Plunger packing | PVDF (polyvinylidine fluoride) with O-ring | PVDF (polyvinylidine fluoride) with O-ring |

.JPG)